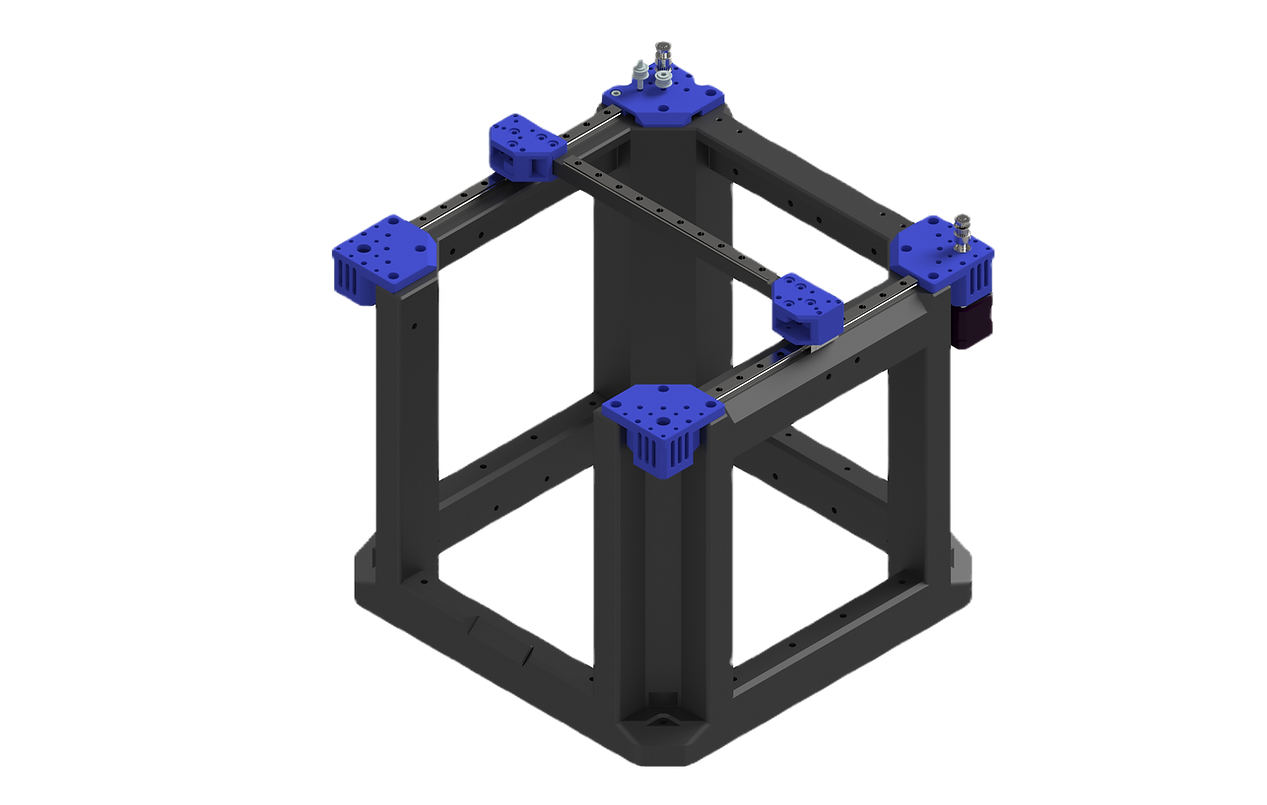

CoreCast 2.0

.

Unlike increasingly mass-produced 3D printer designs, the CoreCast frame exists as a foundation for your limitless hardware combinations, paying homage to RepRap and giving complete freedom for modifications.

Keep as stock, or made compatible with your existing hardware

Every CoreCast frame is fitted with all the necessary mounting points cast directly into place, meaning no more t-nuts while maintaining user-modification and customisation.

DIY Friendly -

Pre-installed hardware

With an open-source approach and utilising Klipper firmware, your CastCore is truly yours. Each machine is issued with a unique serial number which you can assign a (sensible!) name to.

Compatible with your existing hardware

Cast by hand in one solid mass using a rigid composite of resin, quartz and limestone with structural steel reinforcement and all-metal fittings ensures stability and quality.

Built to last at high-speeds and endure vibrations

FormFarm Design Services

In addition to CoreCast printers, specialist form-design solutions can be offered to cater to your personal or business needs. Contact us via the referral form if you wish to discuss further.

Design Consultancy

Have a product idea you wish to bring to market? Or an existing one you're unable to get prototyped properly? Arrange a design consult with Louis.

"With a first-class degree in product design, graphic design & technical engineering work-experience and over seven years working with FDM 3D printing, I'd love to be a part of your problem-solving journey".

Product Production Runs

We are also able to offer batch-production runs and even ship your products directly to your customers. Whether you require prototypes for testing or end-user functional parts, the PrintFarm can help your project into the world.

Additional Services

The FormFarm isn't just another 3D printing company, but a well provisioned workshop offering services in resins, silicones and composites, plastics, wood and metalworking such as cutting/sanding/drilling/tapping. Get in touch today and see if the workshop facilities can benefit your project as they have the CoreCast project.

-Louis Critoph, Designer and Director

"Louis was able to both design and provide us with a long-term solution to a problem concerning an ongoing piping project. It only took a couple of revisions to get the perfect snap-fit tolerances which saved on design cost and turnaround, along with a prompt batch production service".

Joshua - Intelligent Infrastructure

Project Manager

"Through FormFarm, I was able to get large singular ABS parts produced for the stages of my project that would otherwise be impossible to complete without them as other places required a minimum-order quantity. Arrived well packaged and CAD file amendment recommendations specifically for ABS 3D printing were communicated very well".

Peter H.

Engineering Student

I've used FormFarm numerous times now to help me manufacture quality of life and organisational tools for my workstation at home, fitted to specific bespoke measurements and requirements. Louis' collaboration, oversight, attention to details and fast turnaround has always been appreciated, and the end result has always precisely achieved the aims of the initial request.

Grant T.

Video Editor

I am a returning customer for multitude of parts for varying personal projects. FormFarm has shown that they are able to expand upon and improve existing mockups and designs to give best output. Louis always has been my first choice for 3D Printing jobs.

Jack L.

I.T. Technician